PROCEDURE OF PACKING AND PRESERVING GOODS

Limestone after the process of heating in the high-technology furnace when the furnace was selected and sorted by sorting from the sorting screen. The lime was put on the silo containing the product by conveyor. Silo containing the product packaging process is carried out as follows:

From the bottom of the Silo contains the product Lime under the conveyor belt (conveyor belt with swivel trough ensure operation when the belt does not have to stop) to run up directly into the Jumbo bag placed on the pallet on the factory floor (poured During lime conveyor belt from the bottom of silo to the mouth of the lime bag finished products recruited workers again filter out all impurities to ensure that Lime incorporated into the Jumbo bag is 100% clean lime. By the time Lime is released into a full Jumbo bag, the conveyor trough at the end of the conveyor belt will be rotated through another Jumbo bag placed next to the filled Lime Jumbo bag. The bagging process is repeated once every 3 minutes / newspaper. After the Jumbo bag filled with lime, the workers undertook a one-time inspection, tying their bags, dropping the shipping mark after finishing all the forklift tasks to put the jumbo bag in the storage container. Product packaging process.

At present, our company uses 950 x 950 x 1200mm PE coated PE bag with PE layer to pack its products to ensure the absolute quality of goods is not changed during loading and unloading as well as the time Time to move from factory to customer warehouse in every part of the world.

OVERLAPPING PROCEDURE FOR CAR PRODUCTS

For shipping and international ministry Voi Viet Minerals Limited Company we choose the form of using 20DC container as the main transportation method.

In order to facilitate the work of loading and unloading of typical goods using container transport, we use Pallet type 4 for size 1000x1000x100mm pallet equipped with 8 nanopartes 3 nanny bottom to ensure absolute safety in The process of loading, unloading, transporting and disposing of goods at the customer warehouse.

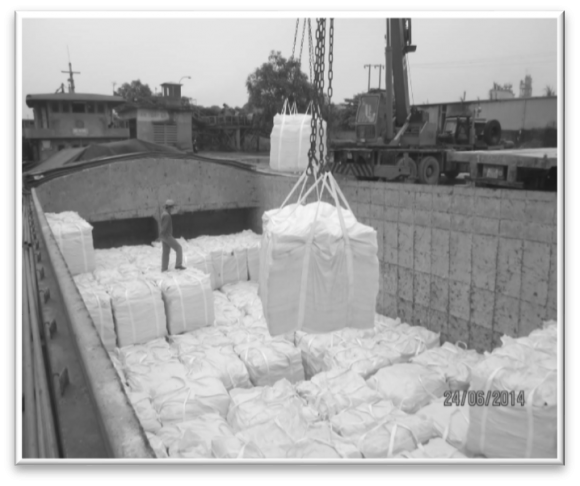

Jumbo Jumbo cart contains the cargo stored and stored in the warehouse. At Vietnam Voi Mineral One Member Limited Company, the loading and unloading of the product is carried out by container lift with 50 ton crane.

When the container is in the loading warehouse, the quality inspection of the shell is carried out by the workers and ensured cont. Heavy duty loading crane, the crane’s task of picking the container shell down to the platform of the forklift truck transports 2 bags / pallet to bring the goods into the container gently. The process goes on sequentially until 20 jumbo bags are loaded onto the container. The workers carry out a final check on the quality of the Jumbo bag, pallet before closing the container.

Containers filled with goods continue to be lifted by the hoisting crane and placed in the car. Container trucks move through the weighing station before leaving the factory to finish the loading and unloading process.

PROCESS OF CLEANING PRODUCTS IN CUSTOMER CUSTOMERS

In order to ensure the quality of goods in customer warehouse Vietnam Voi Mineral Company we recommend customers should use the following options to unload:

1. Plan crane using cont. After that, the forklift pulls the container out of the container with 2 Jumbo bags per pallet until the container is withdrawn. After the goods are withdrawn from the crane container, the container crane is empty and the car returns to the warehouse to finish the unloading.

2. A forklift truck with container bridge. Bridge cont. It is possible to choose steel bridges or bridges built of bricks but must ensure a 3m bridge sphere with a height of 1.6m and a slope of about 8%. When the car cont. Into the unloading position attached to the cont. Forklift cont. Move up the ramp into the contingency 2 jumbo sacks / 1 pallet sequentially out of the cont. And move down the ramp into the storage and use.

The disadvantages of the two types of bridge are as follows: cont bridge. The steel advantage of convenient use, maneuver in the choice of place to ship (can move from one place to another) high aesthetic but high investment cost disadvantages. With bridge cont. Brick building advantages of low investment costs but disadvantages not high durability often have to repair, not flexible in the choice of places to drop.

The specific characteristics of the way of unloading on the car is to equip the forklift with cont., The height of the forklift when handling the cont. Must be guaranteed.

Depending on the actual situation at the warehouse, customers can choose one of the two options to meet the above requirements.

Voi Viet Minerals Limited Company We, with the motto “keep faith”, we strictly manage the production process as well as the process of packaging and loading products to bring customers on. Around the world Lime products are of the best quality.